BYQ Matrix Spring Damping Mounts Made from full automatic intelligent operation manufacturer

Shanghai Songjiang Group Introduce to everyone: BYQ Matrix Spring Damping Mounts Made from full automatic intelligent operation manufacturer Information, Shanghai Songjiang Group designed a matrix Spring Damping Mounts for dry-type transformers, which is mainly used for shock absorption and noise reduction of transformers, We have provided transformer shock absorbers for many bureau maintenance projects.

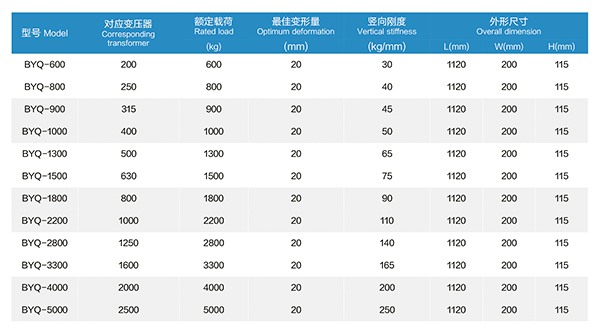

Introduction of BYQ type matrix Spring Damping Mounts:

BYQ Spring Damping Mounts are composed of multiple groups of large outer diameter, large deformation springs, upper and lower steel plates, and rubber anti-skid pads;

Mainly applicable to modern computer room transformers, such as cloud data center transformers;

The product has the advantages of large deformation, stable performance, good isolation effect, and service life of more than 10 years;

The seismic isolation and sound insulation effect is good, the isolation rate of the transformer can be more than 90%, and the sound insulation can reach 15~20dB;

The ratio of the lateral stiffness to the vertical stiffness of the shock absorber is greater than 1.5, and the stability is good;

Simple and convenient installation and construction, low cost of transformation;

Description of BYQ type matrix Spring Damping Mounts:

1. One transformer uses 2;

2. The corresponding transformers in the table are mainly copper core transformers. If it is an aluminum core transformer, it needs to be calculated, and the aluminum core is much lighter;

3. The effect before and after installation is increased by 90%;

4. Delivery time: 7 days;

5, 10 years warranty;

6. Jiangsu, Zhejiang, and Shanghai support door-to-door installation services (with Jiangsu power supply system installation qualification);

7. Detection: night detection, including two detections (before and after installation, the door-to-door installation user includes this);

8. A single product is about 50kg;

Related Link: Various pipeline industry project case of molded rubber expansion joint from shanghai songjiang group