As a crucial part of the Shanghai World Expo Urban Best Practices Area redevelopment project, Lithium Bromide (LiBr) chiller units play an indispensable role in cooling and air conditioning systems. These units ensure that the indoor temperatures remain comfortable. This article will delve into how Songjiang’s rubber expansion joints seamlessly integrate and enhance the performance of these vital systems.

Lithium Bromide Chiller Units – The Backbone of Cooling:

Lithium Bromide chiller units represent the epitome of absorption refrigeration equipment widely used in buildings. They generate cooling effects by absorbing and releasing water vapor. Powered by natural gas, steam, or electricity, Lithium Bromide chiller units are pivotal in maintaining comfortable indoor temperatures.

Outstanding Features of Songjiang:

At Songjiang, we take pride in our commitment to excellence, which is our hallmark. We don’t just offer connectors; we provide rubber expansion joints renowned for their resilience, durability, and adaptability. Through precision engineering and rigorous testing, we ensure that our joints perform optimally in diverse and demanding environments.

The Crucial Role of Rubber Expansion Joints:

In retrofitting Lithium Bromide chiller units, rubber expansion joints play a critical role for the following reasons:

Adapting to Pipe Variations: Retrofit projects typically necessitate adjustments or expansions of existing pipe systems. Rubber expansion joints excel in flexibility and stretchability, accommodating variations in pipe dimensions due to temperature fluctuations, vibrations, or other factors, ensuring a secure connection.

Absorbing Vibrations and Shocks: Retrofit projects can induce vibrations and shocks within pipe systems. Rubber expansion joints effectively absorb these vibrations, reducing the impact on pipes and equipment, thereby enhancing system stability and longevity.

Compensating for Thermal Expansion: Pipes experience thermal expansion and contraction at high-temperature operating conditions. Rubber expansion joints ingeniously compensate for these dimensional changes, preventing pipe damage or stress due to temperature fluctuations.

Quality and Performance Requirements:

Retrofit projects impose stringent demands on rubber expansion joints:

High-Temperature and Corrosion Resistance: Operating within flue gas systems, rubber expansion joints must exhibit high-temperature and corrosion resistance to ensure long-term stability.

Gas Leak Prevention: Rubber expansion joints must effectively prevent gas or medium leaks to ensure system safety and environmental compliance.

Vibration Absorption and Noise Reduction: Given the importance of vibration and noise control in retrofit projects, rubber expansion joints typically need to possess the capability to absorb vibrations and reduce noise, enhancing operational comfort.

The authentic photo of songjiang rubber expansion joints for Lithium Bromide Chiller Units in Shanghai

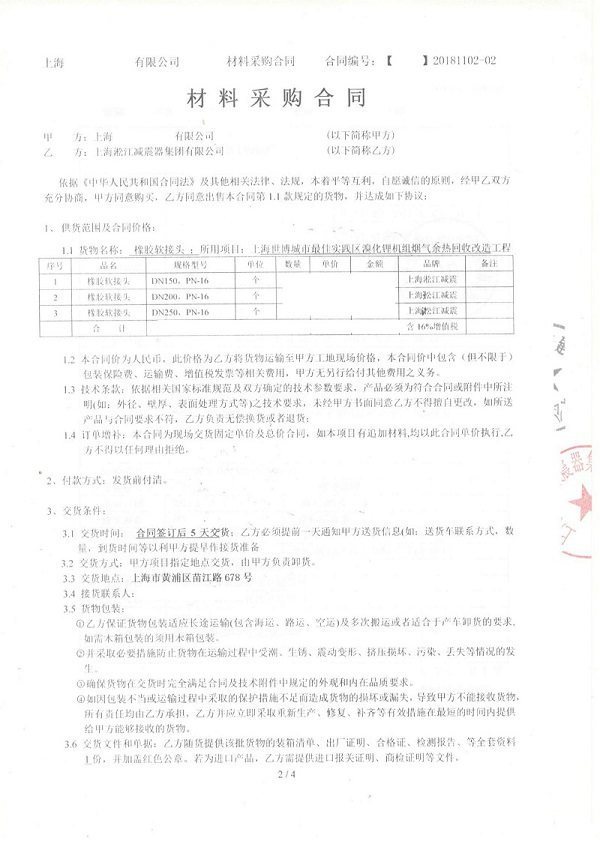

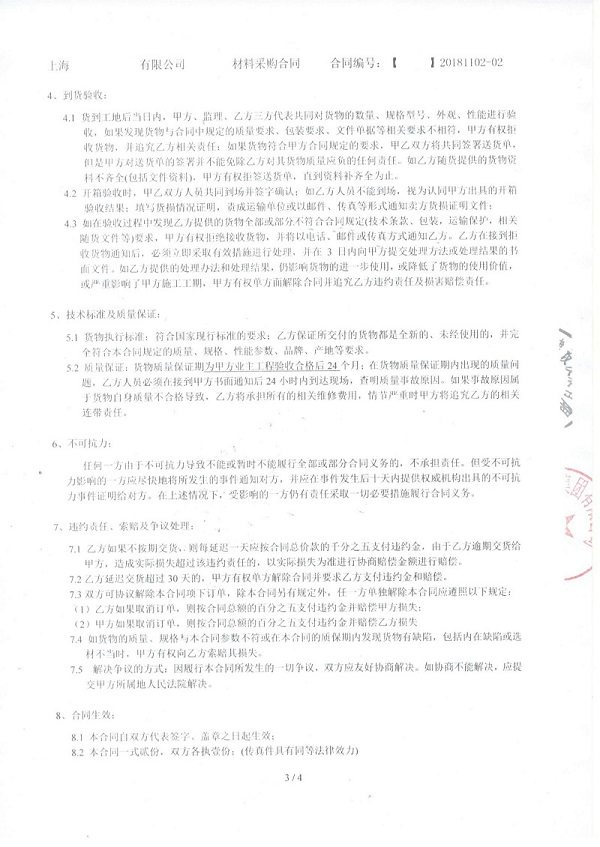

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

Songjiang’s rubber expansion joints seamlessly integrate with Lithium Bromide chiller units, elevating their performance. These joints offer exceptional adaptability and performance, ensuring their smooth integration into diverse environments. Looking ahead, Songjiang remains dedicated to innovation and sustainability, providing support for outstanding engineering solutions. We cordially invite individuals from all walks of life to join us in building a comfortable and efficient world together.

Related links:KXT DN25 Single sphere Non Metal Expansion Joint application for pressure water supply equipment