Suzhou Bosch Automotive Components stands as a beacon of excellence in the automotive industry, known for its commitment to quality and innovation. Established in 1999, Suzhou Bosch has been at the forefront of automotive engineering, catering to various product divisions and delivering cutting-edge solutions. This case study delves into the seamless integration of Songjiang Rubber Expansion Joints and Metal Expansion Joints into Suzhou Bosch’s automotive systems, showcasing its transformative impact on performance and reliability.

Suzhou Bosch Automotive Components: Pioneering Automotive Solutions

Suzhou Bosch Automotive Components, founded in 1999, has earned a reputation for excellence in automotive component manufacturing. With a focus on innovation and customer satisfaction, Suzhou Bosch has obtained TS 16949 quality system certification and has been recognized as a high-tech enterprise. Its R&D technology center, situated in Xinglong Street, has been acknowledged by the Jiangsu provincial government as a key R&D center. Suzhou Bosch’s commitment to excellence is evident in its diverse product portfolio and its highly specialized workforce of 6,500 employees, ensuring the growth of each division’s business.

Metal Expansion Joints: Enhancing Automotive Performance

Metal Expansion Joints have emerged as indispensable components in automotive manufacturing, offering versatility and reliability. These joints effectively counter temperature and pressure fluctuations within vehicle systems, ensuring stability and longevity. Moreover, Metal Expansion Joints absorb vibrations and reduce noise transmission, enhancing passenger comfort and vehicle durability. Their ability to compensate for axial and radial displacements safeguards against structural damage, optimizing system integrity.

Case Study: Suzhou Bosch’s Integration of Metal Expansion Joints

Suzhou Bosch Automotive Components has seamlessly integrated Metal Expansion Joints into its automotive systems, ushering in a new era of performance and reliability. In the chassis control system, Metal Expansion Joints compensate for temperature-induced expansions, ensuring precise alignment and superior handling dynamics. Furthermore, in the exhaust system, Metal Expansion Joints mitigate vibrations and minimize noise transmission, resulting in a smoother and quieter driving experience.

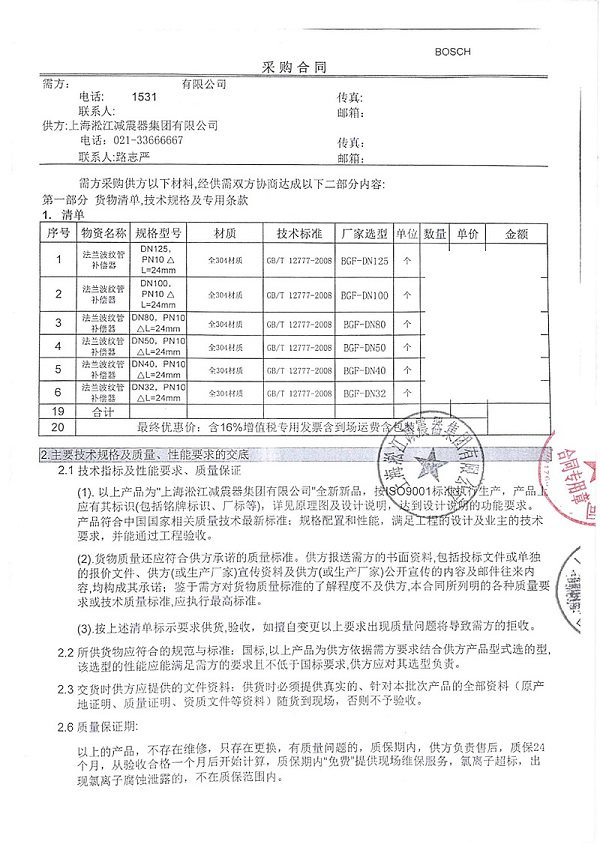

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

Within the powertrain system, Metal Expansion Joints facilitate seamless torque transmission while mitigating axial and radial displacements, optimizing power delivery and minimizing drivetrain wear. Additionally, in fluid transmission systems, Metal Expansion Joints serve as reliable seals, preventing leakage and enhancing fluid transfer efficiency between components.

Related links:BGF Type DN25 stainless steel Metallic Compensator application for high-altitude pipeline

![[China Forging Machinery Co., Ltd. (CFM)] Oil-resistant NBR molded rubber expansion joint with reasonable prices for Oil pipeline contract](https://www.rubber-expansion-joint.cn/wp-content/themes/xsmake.sj/timthumb.php?src=https://www.rubber-expansion-joint.cn/wp-content/uploads/2022/06/Oil-Pipeline-molded-rubber-expansion-joint-1.jpg&h=400&w=500&zc=1)